One camera can handle the defect detection of all product categories, saving space, debugging efforts, and costs!

For traditional 2D detection, when dealing with different types of defects and flaws, are you still troubled by the following problems?

• Multiple workstations need to be set up for the detection.

• The detection machine requires a large installation space.

• It takes a long time to debug the lighting for detecting defects.

• It is difficult to replicate the detection solution on the production line.

• The imaging consistency of the detection solution is poor.

Aiming at the above pain points and difficulties in industry applications, the dedicated R&D of a future-oriented multi-image platform and Hybrid Data Camera has proposed a set of implementable integrated solutions from hardware to algorithms, which can solve your problems.

Next, let me introduce to you this vision solution that is worth learning about.

Product Overview of the Multi - Image Platform

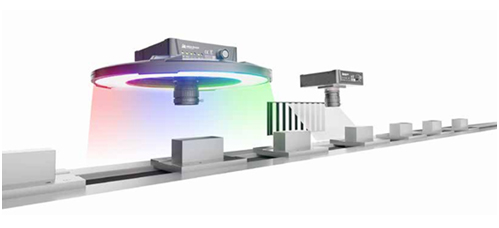

The Hybrid Data Camera is a leading vision inspection hardware. It has built - in imaging modes such as photometric stereo, phase deflectometry, etc., which are used for detecting defects and flaws on the surfaces of objects made of different materials.

The camera has powerful real - time processing capabilities for original images. It can directly output high - quality, high - information - density 2D and 2.5D images, which helps improve the efficiency of AI training. It also helps users increase the detection rate of defects and flaws, shorten the project implementation cycle, and reduce the overall cost of inspection projects.

Product Positioning

It is a vision hardware platform for industrial inspection, supporting multiple imaging modes (photometric stereo/phase deflectometry/2D pre - processing).

Core Functions

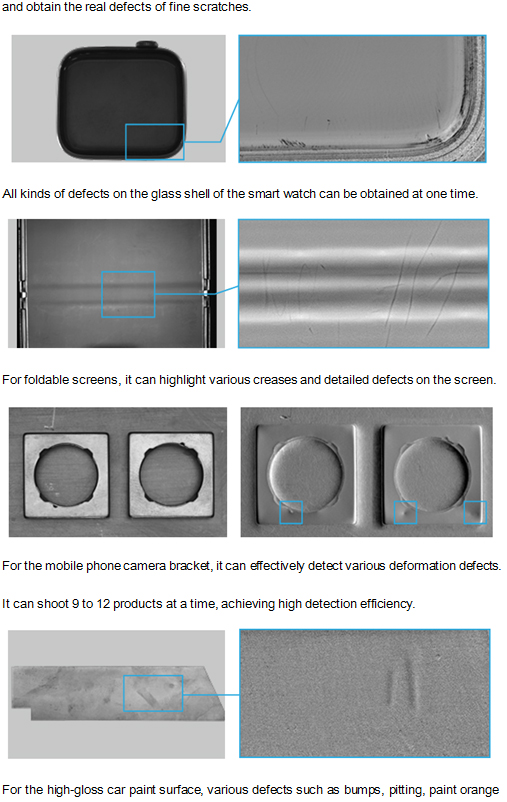

Through the integration of high - precision imaging and algorithms, it can detect surface defects (such as bumps, scratches, dirt, etc.) on objects. It is suitable for various materials including metals, plastics, glass, coatings, etc.

Core Advantages

- Abundant Data: It can output up to more than 40 images at most, which can highlight different types of defects and flaws (including original 2D images, calculation images, and calculation images in two 2.5D modes. Users can independently select the types and quantities of the output images).

- Highly Integrated: It is equivalent to multiple workstations, reducing the traditional 2D lighting system. With built-in light source control, there is no need for an additional controller, reducing the deployment complexity.

- Greater Flexibility: The same set of system can effectively detect a variety of defects and flaws.

02

Key Technologies

Multiple imaging modes are available for flexible selection.

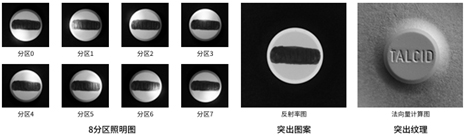

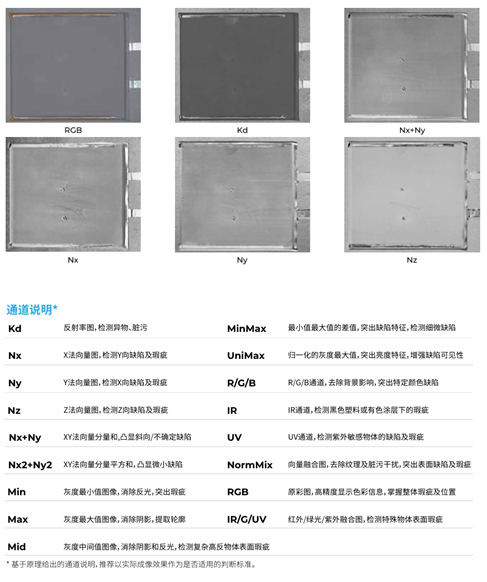

Photometric Stereo Mode

• Technical Principle

It is applicable to diffuse reflection objects and some highly reflective objects.

The Hybrid Data Camera controls the multi-spectral partition light sources to achieve multi-angle illumination and shooting. And it conducts real-time processing of the images through various hardware algorithms, eliminating all kinds of interferences, obtaining information such as the surface normal vectors and reflectivity of the objects, and outputting multi-channel images.

The photometric stereo mode can effectively detect defects and flaws such as bumps, pits, slight scratches, abnormal colors, tool marks, dirt, etc. on the surfaces of diffuse reflection or some highly reflective objects.

• Multi-spectral Partition Light Sources

• Technical Principle

It is applicable to diffuse reflection objects and some highly reflective objects.

The Hybrid Data Camera controls the multi-spectral partition light sources to achieve multi-angle illumination and shooting. And it conducts real-time processing of the images through various hardware algorithms, eliminating all kinds of interferences, obtaining information such as the surface normal vectors and reflectivity of the objects, and outputting multi-channel images.

The photometric stereo mode can effectively detect defects and flaws such as bumps, pits, slight scratches, abnormal colors, tool marks, dirt, etc. on the surfaces of diffuse reflection or some highly reflective objects.

• Multi-spectral Partition Light Sources

Multi-spectral

It can achieve multi-spectral band illumination including red, blue, green, infrared, ultraviolet, white, etc., and is flexibly applicable to a variety of scenarios.

Multi-channel image output

It improves the detection rate and accuracy of various defects and flaws.

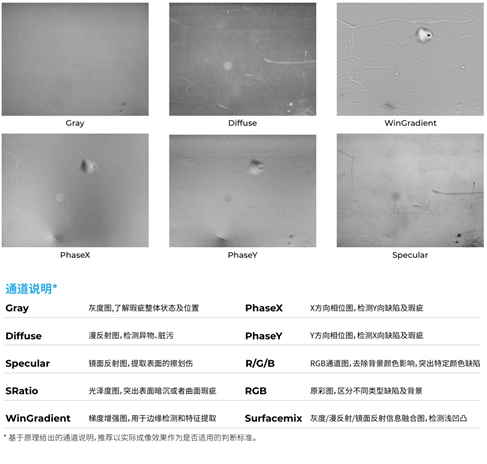

Phase Deflectometry Mode

• Technical Principle

It is applicable to highly reflective and transparent objects. In the phase deflectometry mode, by adjusting parameters such as the period, projection direction, or pattern style of the light source stripe pattern, it can effectively capture defects and flaws such as bumps, slight scratches, and tiny pits on the object surface.

• Programmable Screen Light Source

The camera can be controlled synchronously without the need for a light source controller.

There is no delay. It can project a variety of patterns, and parameters such as the period and screen refresh rate are adjustable.

• Multi-channel image output

It improves the detection rate and accuracy of various defects and flaws.

The unique 2D pre-processing algorithm makes imaging more straightforward.

1. Black-and-white 2D mode: With the help of hardware HDR and multiple averaging, an image with an ultra-high signal-to-noise ratio can be obtained.

2. Color 2D mode: The HSV function. The CMOS directly outputs the HSV color model, which can quantify colors more finely and highlight tiny color differences.

3. RGB enhancement: The RGB enhancement algorithm can effectively identify the color changes of dark objects and can significantly improve the detection rate of abnormal colors or other minor flaws.

03

System Setup

It can be completed in three steps.

The first step: Determine the material of the object to be measured and select the shooting mode and match it with the light source.

Diffuse reflection objects: Photometric stereo mode, matched with a multi-spectral partition light source;

Highly reflective objects and transparent objects: Phase deflectometry mode, matched with a programmable screen light source;

The second step: According to the detection accuracy, select the camera resolution (resolutions ranging from 8.1M to 20M are available for selection).

The third step: Select a C-mount interface lens.

The table above is the hardware matching table.

04

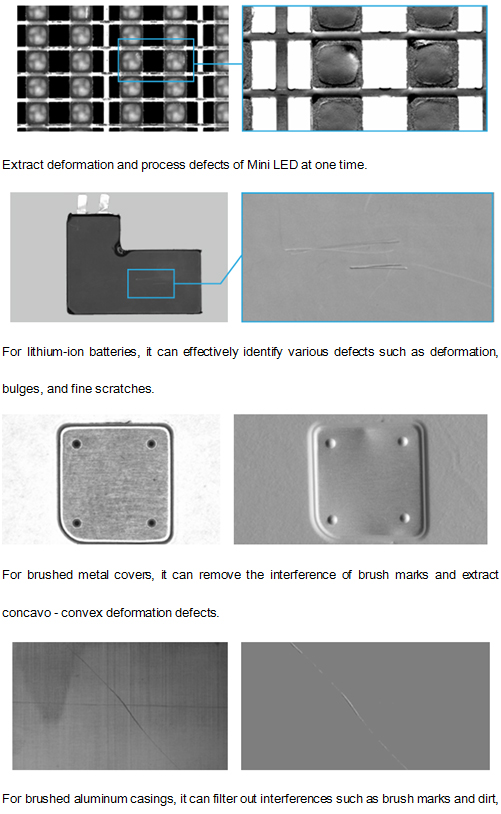

Application Scenarios

peel, and scratches can be obtained at one time.

05

The Hybrid Data Camera is born for defect and flaw detection.

Time Advantage

It has a high degree of integration, allowing for easy deployment. It can detect various defects and flaws at one time.

Hardware Advantage

It reduces the types and quantities of workstations and there is no need for additional customization. It also reduces the space occupied by the machines.

Manpower Advantage

It is convenient to use and easy to get started. Only simple training is required, and not much experience is needed.

There is no need for cumbersome debugging.

It can easily achieve the replication of production lines.

It effectively reduces the time for production line replication and debugging, and ensures the system stability and imaging consistency after the production line is replicated.

|